1

/

of

6

CSF G8X M2 M3 M4 Level-Up Manifold Cooler (8233)

CSF G8X M2 M3 M4 Level-Up Manifold Cooler (8233)

Regular price

$6,599.00 USD

Regular price

Sale price

$6,599.00 USD

Unit price

/

per

Couldn't load pickup availability

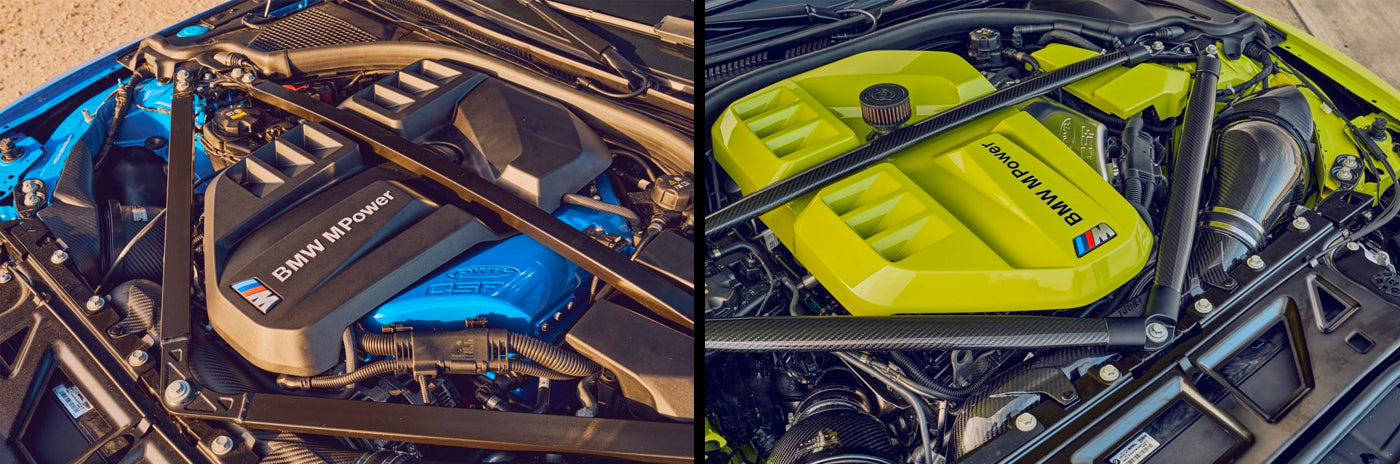

The CSF "Level-Up" Charge-Air-Cooler Manifold for 2021+ BMW M2 M3 M4 features a billet design, bar and plate intercooler core and CNC fuel rail all with a direct-replacement fit! Proven to lower intake manifold temperatures by up to 15%.

Vehicle Fitment:

2021-2024 BMW M2 M3 M4

G80 G81 G82 G83 G87

• Fits auto and manual models

• Fits AWD and RWD models

Injector Suggestions:

• ID1050x 1050.34.14.14.6

• CSF recommends using Injector Dynamics (ID) injectors for the best performance – the most commonly used injector for this engine has been ID 1050.34.14.14.6.

• The fuel rail aperture for each cylinder has an optimized 7mm opening for compatibility with most commonly used high performance injectors.

| Part Number: | Finish: |

| 8233 | Raw Billet Aluminum |

| 8233B | Thermal Black Heat Dispersion Powder-Coating Finish |

| 8233C *Special Order* | Custom Powder-Coating Finishes from CSF are available. Please call STM to customize and order. Extended wait times will apply. |

The CSF S58 “Level-Up” Charge-Air-Cooler Manifold comes with everything you need to install and setup. The only thing not included are injectors as most customers will select their preferred choice and required size based on their build. There is also a complete instruction guide for both professional installers and ambitious DIYers. Like all CSF Products, this kit is a true "drop-in fit" installation.

Features:

• Faster recovery of Intake Air Temperatures (IATs)

• 40-60°F average reduction of Intake Air Temperatures (IATs) compared to OEM at 45 PSI

• No pressure drop compared to OEM core

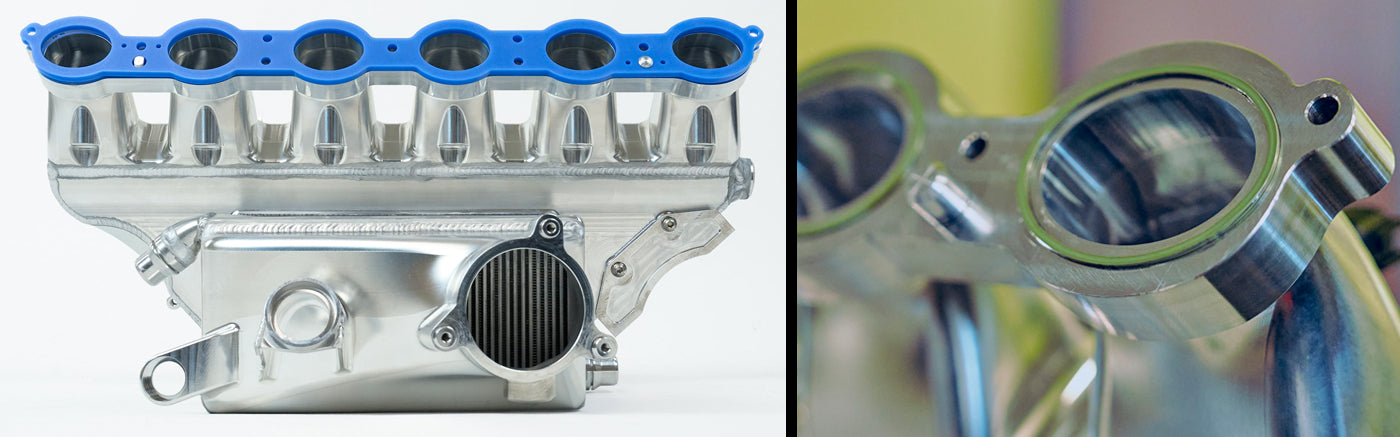

• Ultra strong CNC Billet construction replaces weak plastic tanks with crimped-on gasket sealing core.

• High performance bar/plate intercooler core by PWR pressure tested to 120psi*

OEM cooler is a tube/fin core which is prone to failing at pressures over ~27psi

• Top feed port injection w/ included fuel rail (w/ CNC machined block-off caps included for non-use)

• Integrated Nitrous/Methanol Injection Ports

Individual ports for each runner for maximum control

• Integrated vacuum and parameter pad to measure additional parameters

• Easy access to spin-off oil filter*

• Integrated breather port for easy bleeding of air from the water side of the manifold*

• Included KIYLEX Thermal Rejection Manifold Spacer*

Made from KIYLEX® – A patented revolutionary high-performance final stage polymer

Acts as a thermal barrier that dissipates heat between the cylinder head and intake manifold

Proven to lower intake manifold temperatures by up to 15%

Lowers Intake Air Temps (IATs)

• All necessary brackets, hardware, and instructions to install

• Raw Billet Aluminum Finish (#8233)

• Thermal Black Heat Dispersion Powder-Coating Finish (#8233B)

• Available in custom colors from the leader in BMW cooling customization (#8233C)*

• True Plug-and-Play “Drop-in Fit” Installation – Requires Absolutely No Modifications.

• OEM level of fit and finish

• Limited Lifetime CSF Warranty

Purchase Includes:

• Manifold

• Fuel Rail

• Plenum Gasket

• Install Hardware

Read More from CSF:

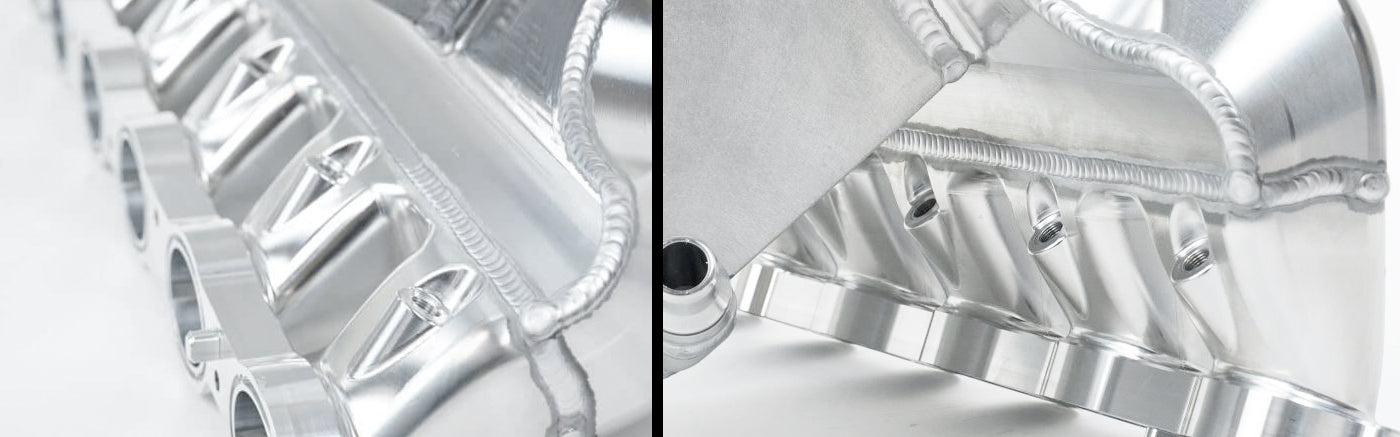

CSF has the largest plenum volume The joining of sections on any part can take up some space. Depending on the joining method, the required space will vary. In the case of the CSF Radiator, TIG Welding the billet aluminum sections together offers the strongest and most space efficient method. If you look inside the plenum and runners you can see the smooth transitions between each piece that maintains the smoothest airflow and the largest volume possible.

Welded not Gasketed

Gaskets have their place in automotive engineering and construction. There is nothing inherently wrong with them as they are necessary for countless applications. However, in the case of manifold construction, they have their drawbacks. The required provisions for securing two pieces of a manifold with a gasket require additional space and materials. The extra material inside the plenum for bolts to secure two pieces of the manifold together reduces plenum volume.

Additionally, the gasket creates an extra weak point. For those running modest boost increases this may not be an issue, but CSF knows many BMW owners want to push for the most performance possible. This is why CSF elected the strongest construction possible to give our customers the strongest and most durable manifold possible.

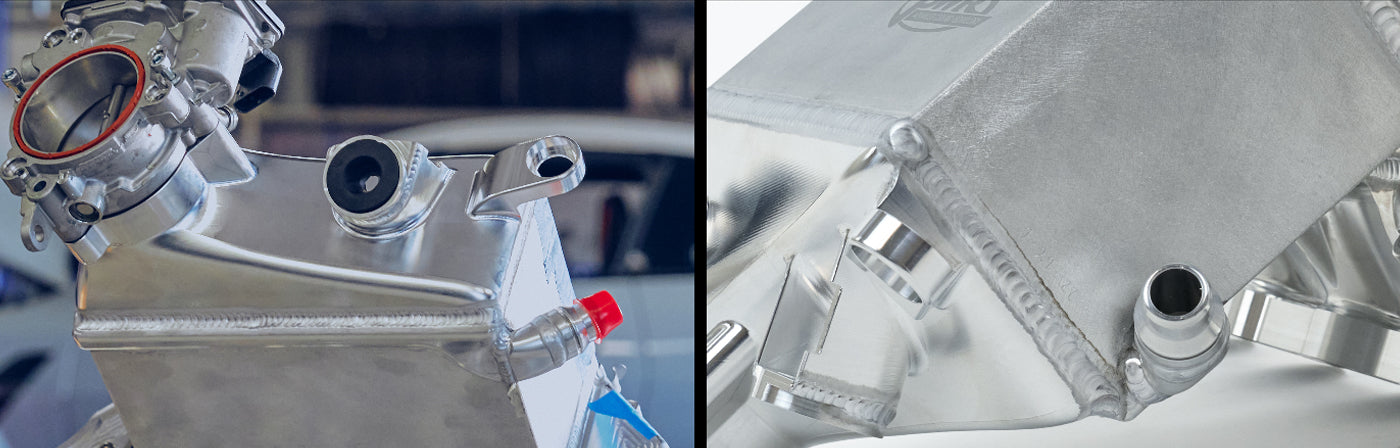

Water Flow + Bleeder

Water flow is just as important as air flow in an Air-To-Water system. Many companies will focus on the flow capabilities of their intercooler core, but forget to consider the flow in and out of the manifold. CSF spent extra time engineering and developing the water inlet and outlet channels for the intercooler core. The design ensures the most even flow of water through the cooler for optimal heat dissipation.

CSF also added a bleeder valve at the top of the charge air cooler to make the installation process a lot easier. Anyone who has installed a charge-air-cooler knows the frustration of getting all the air out. This bleeder value speeds up the process immensely and adds peace of mind that the system is properly bled before start up.

Air Guides

Proper airflow is essential for performance and reliability for any engine. This becomes even more important as you start tuning for a lot more power. If you have uneven air distribution between the plenum and runners you can have some cylinders not getting enough air and leading to potentially catastrophic failure. CSF and PWR used advanced CFD (Computational Fluid Dynamics) Software to engineer the airflow through the plenum. Special air guides were added to ensure each cylinder gets full airflow.

While the plenum can function fine without such air guides, CSF went the extra mile knowing customers will be pushing the S58 platform far past what BMW intended. The extra precaution is just one of many features that make the CSF “Level Up” Manifold stand out from the competition.

OEM+ Fit and Installation

CSF Prides itself on designing and offering drop in fit cooling solutions that require no modifications to install. The CSF S58 “Level Up” Charge Air Cooler Manifold is no exception to that design philosophy. Special care was taken to ensure the simplest installation process possible with the finest attention to details.

Brackets and Stays

No one likes having to leave factory harnesses and hoses unsecured after installing a new part. Every wire and wire have been accounted for with OEM+ style mounting provisions. Many of these details are exclusive to the CSF Manifold.

- Stand-offs on top of the plenum secure the emissions lines (exclusive).

- The included removable engine cover mounting pin matches the billet finish perfectly (exclusive)

- CSF’s front wire harness mounting bracket is adjustable for better fit and easier installation (exclusive). The design matches the OEM bracket for a perfect OEM fit and includes holes for the OEM harness clips to secure to.

- The hose clip harness stay on the side of the manifold keeps the emissions line secure and in place (exclusive).

- The overflow tank is securely mounted in the factory location and reuses the factor grommet for the lower mounting point.

O-Rings / Gaskets

Each intake runner is machined for the OEM O-Rings with the factory style “teeth” to secure them (exclusive feature). This keeps the O-Rings from falling out during prep and installation. The Billet dowel pins between runners 1 and 2 as well as 5 and 6 both help secure the Thermal Rejection Competition Spacer. They also help keep the manifold aligned while bolting it into place. All in all, these features will make installation far less frustrating and were developed after test fit installs before final production.

KIYLEX Thermal Rejection Competition Spacer

Made from KIYLEX®, a patented revolutionary high-performance final stage polymer. KIYLEX® is as strong as aluminum and can withstand temperatures up to 1100°F. This spacer is designed to insulate the intake manifold from conductive heat transfer from the cylinder head.

This thermal barrier reduces manifold temperatures which helps lower Intake Air Temperatures (IATs), improve charge air cooler efficiency, and combats heat soak. CSF is the exclusive distributor for the KIYLEX® Intake Manifold Spacer for the S58 and B58 Motor.

How it works and why you need it

The addition of the Thermal Rejection Spacer is especially useful for Drag/Roll-Racing Events where vehicles typically sit in staging lanes in-between racing. This causes extreme heat soak to the liquid-to-air manifold as there is not sufficient airflow passing over the front mount heat exchanger when the car is idling (which is responsible for cooling the charge air fluid that runs through the manifold). This causes the starting IATs on subsequent runs to be higher than on the initial run.

The Billet Aluminum and 100% TIG Welded construction offers incredible strength, which allows the manifold to withstand higher boost pressures compared to the OEM plastic manifold. However, aluminum has higher thermal conductivity than plastic resulting in a higher rate of heat transfer between the cylinder head and manifold. Thermal Rejection Spacer reduces heat transfer between the two metal components (cylinder head & manifold). The spacer absorbs the heat from the cylinder head and dissipates it rather than transferring it to the manifold.

Nitrous / Methanol Ports

The CSF Manifold also features individual 1/8″ NPT ports on the underside of each intake runner. These ports can be used for Nitrous or Methanol injection. Not only is the location of the ports optimal for directly injecting your preferred go fast juice, but they are also hidden from plain view. This allows for a stealthy installation that is easy to conceal from unwanted attention.

Vacuum and Parameter Pad

A feature that was added to the B58 “Super” Manifold (CSF #8200) due to popular demand was a 3 Port Pad. This allowed customers to run extra sensors and provided additional vacuum sources. With such positive feedback for the feature CSF decided to include it from the start on the S58 Manifold. Located on the side of the plenum, it is easy to access and offers plenty of room for your chosen accessories.

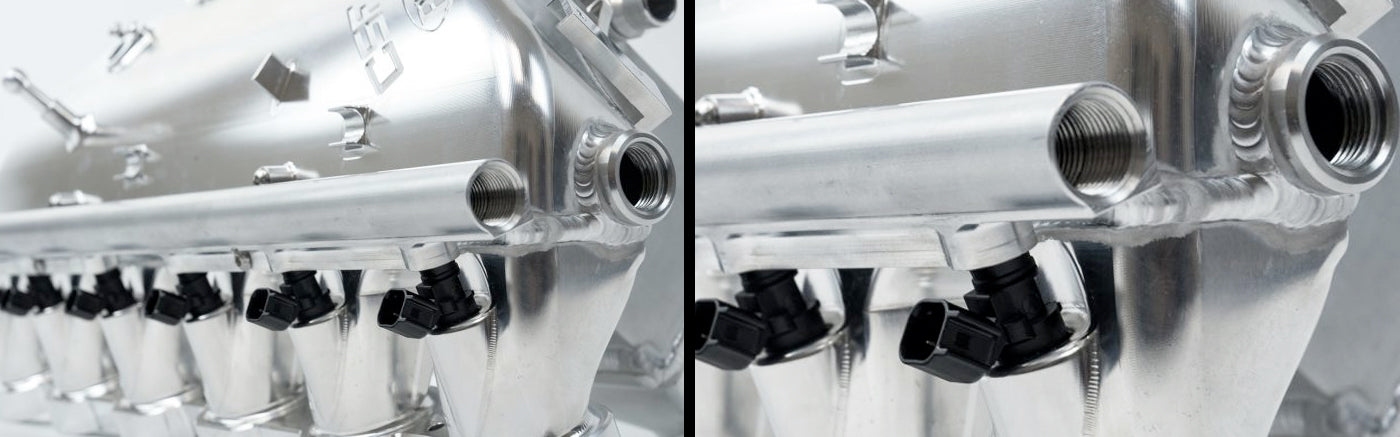

ORB Fitting Machining

There are two -10 ORB (O-Ring Boss) Fittings machined into the manifold. The lower is for crankcase ventilation and is standard use on all applications. ORB was chosen for its optimal sealing performance and the tolerances the fittings can produce. The Hard Anodized thin wall aluminum quick connect hose fittings offer the thinnest possible spec while being incredibly strong. This removes the potential restriction in air flow, an optimal seal, and the modularity to block off either fitting with included -10 ORB bungs.

Oil Filter Recess

Have you ever done an oil change and wondered why some jerk decided to make the oil filter impossible to get to? Well, you’re not alone. CSF wanted to avoid this type of frustration and included a special indent for easier oil filter access into the manifold. While this might seem like an obvious design feature to some, not all of our competitors are as thoughtful.

The designed protrusion above the recess was tested with CFD software to ensure smooth air delivery into the rear runners for the best possible airflow. The CSF Manifold is the only one to offer this feature and the only one that can run aftermarket oil filter caps.

Plug and Play Port Injection

Every manifold includes an extruded fuel rail that has been machined to offer maximum flow for any applicable injector size. Whether you want to run standard pump gas, race gas, or E85, the fuel rail will work with your system. The AN-8 fuel rail comes with -8 internal hex plug fitting to use if running an OE style feed only fuel system but can be removed for a fuel system upgrade with fuel return.

Fuel rail aperture for each cylinder is an optimized 7mm opening for compatibility with most commonly used high performance injectors.

CSF recommends using Injector Dynamics (ID) injectors for the best performance – the most commonly used injector for this engine has been ID model # ID1050x 1050.34.14.14.6

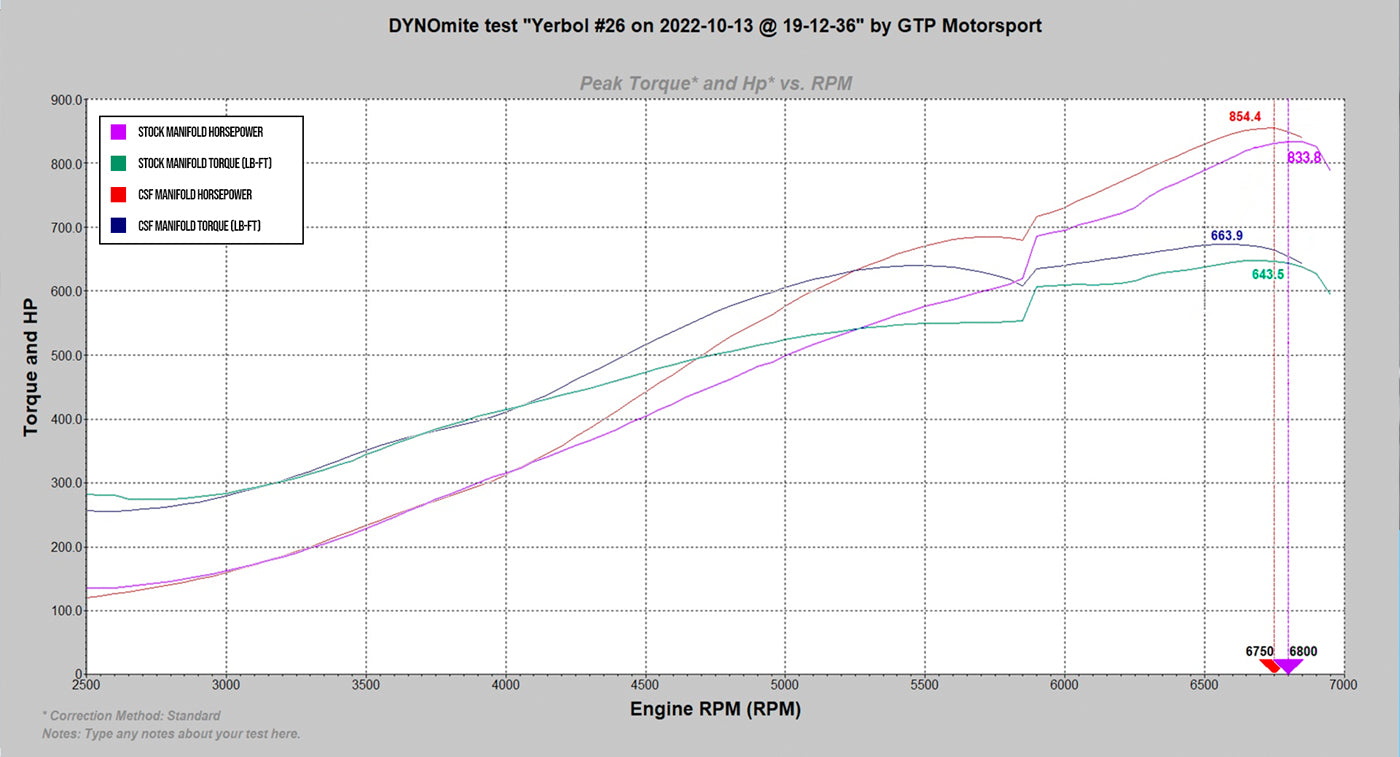

Dyno Testing

Testing was conducted on GTP’s Dynomite AWD2500 Dyno. Data was collected using an AEM CD-7. Baseline pulls were performed with the car tuned with 44 PSI as the target boost level. Actual boost level produced by the turbos in the OEM tests was 41.6 PSI. The post manifold installation pulls were performed with the car tuned with 45 PSI as the target boost level. Actual boost level produced by the turbos in the CSF tests was 41.5 PSI.

Note: we were very lucky the OEM Manifold lasted as long as it did. They have been known to fail at as low as 30 PSI. It did start leaking on some of the test runs but did not fail by some miracle.

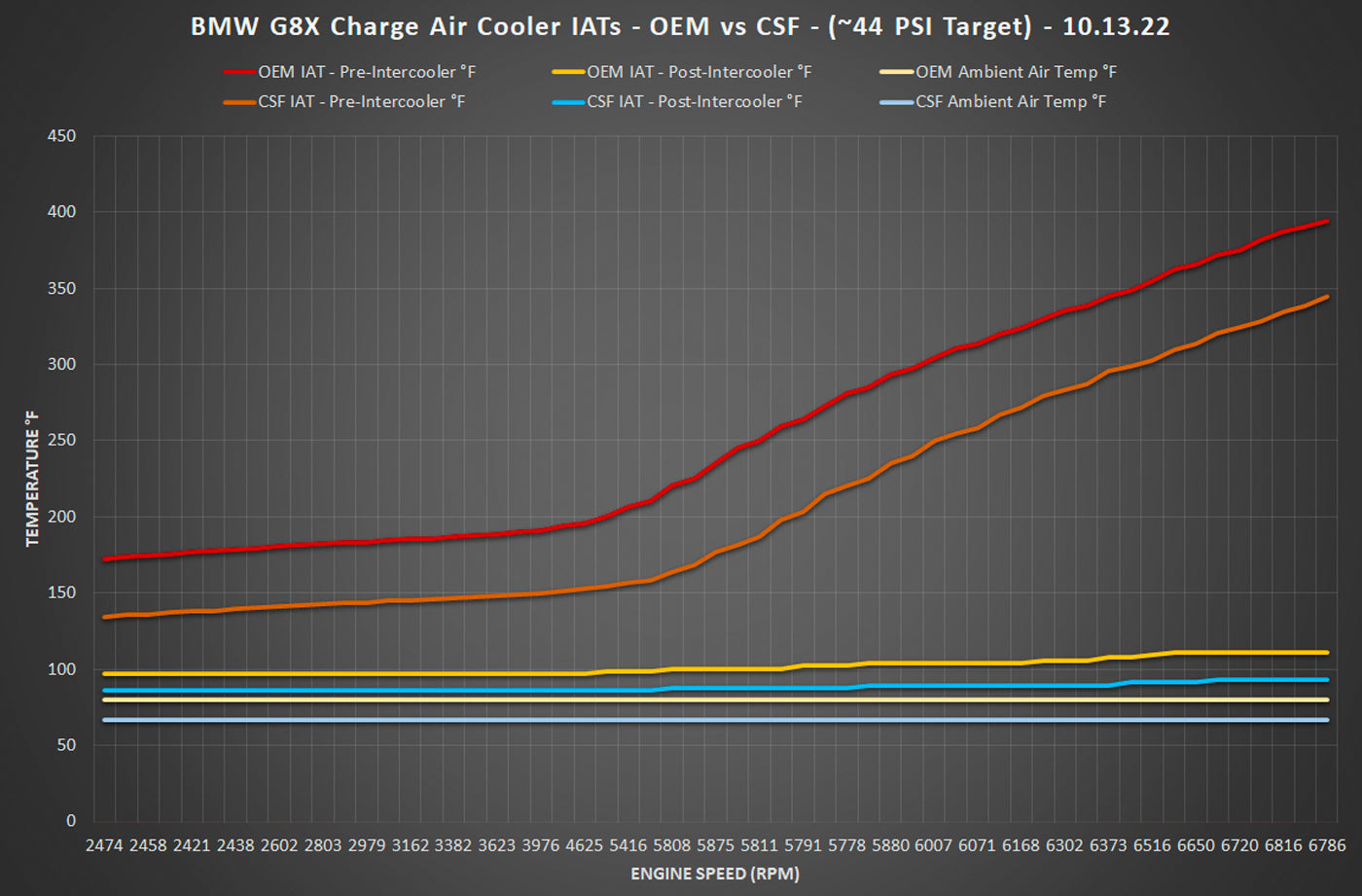

Efficiency Testing

We could easily throw out some big numbers and percentages without explaining what is really being shown by the data. The chart below shows the data from the same dyno pulls in the Horsepower & Torque section above.

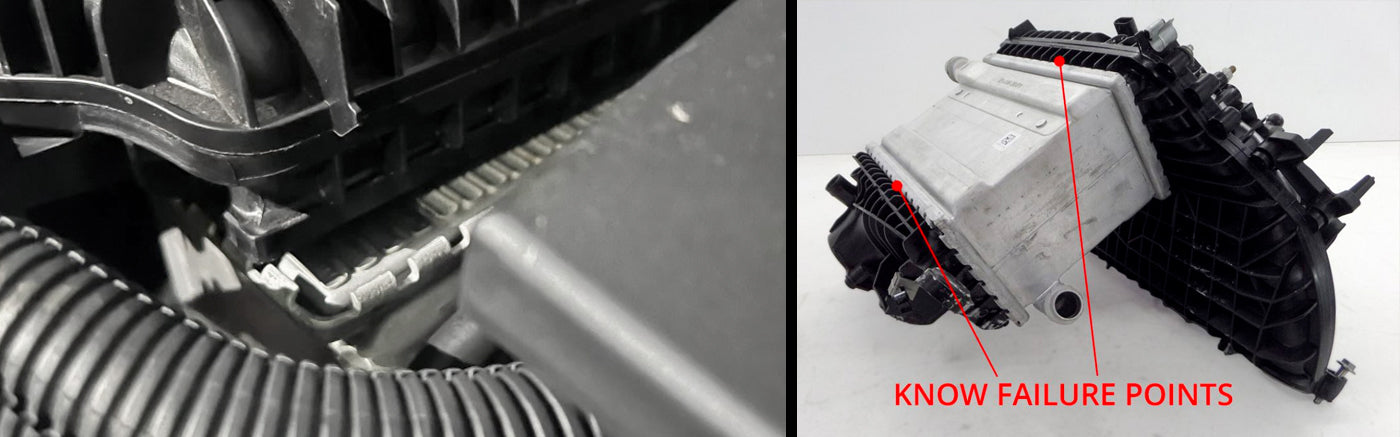

OEM Manifold Failure at Plenum & Core:

The OEM manifold has been proven to commonly fail around 30-35 PSI of boost pressure. This obviously limits potential power you can make with this motor. We were lucky enough to have the OEM Manifold we were testing with hold up to several test runs at the targeted 44 PSI (Turbos could only produce 41.6 PSI). So in order to safely run more than 30-35 PSI consistently, you need a manifold that is strong enough to hold up to the pressure. The CSF by PWR Core is rated up to 120 PSI and the 100% TIG Welded Billet construction can handle far more pressure than that.

In summary, the Factory Charge-Air-Cooler is very efficient like everyone claims. However, CSF and PWR were able to engineer a much larger and stronger Charge-Air-Cooler capable of much higher horsepower and pressure while still improving efficiency.

It’s Time to Level-Up!

This has been the most heavily invested upon product that CSF has ever produced. The time spent in Research, Development, Testing, and Production has been monumental. However, we feel like it’s all been worth it. It’s about our pride in the BMW market and being the best. Based on the fact that we’ve sold 98 of these kits already before this official press release has been published, proves to us that the market already agrees. The confidence the BMW community has in CSF’s cooling products and our reputation has been humbling. With this official press release we really wanted to give every last detail of this manifold the attention it deserves. There are other choices out there, and I’m sure there will be more aftermarket options chasing us in the future.

See more CSF Products

Share